Blast Nozzles

Showing 16–30 of 42 results

-

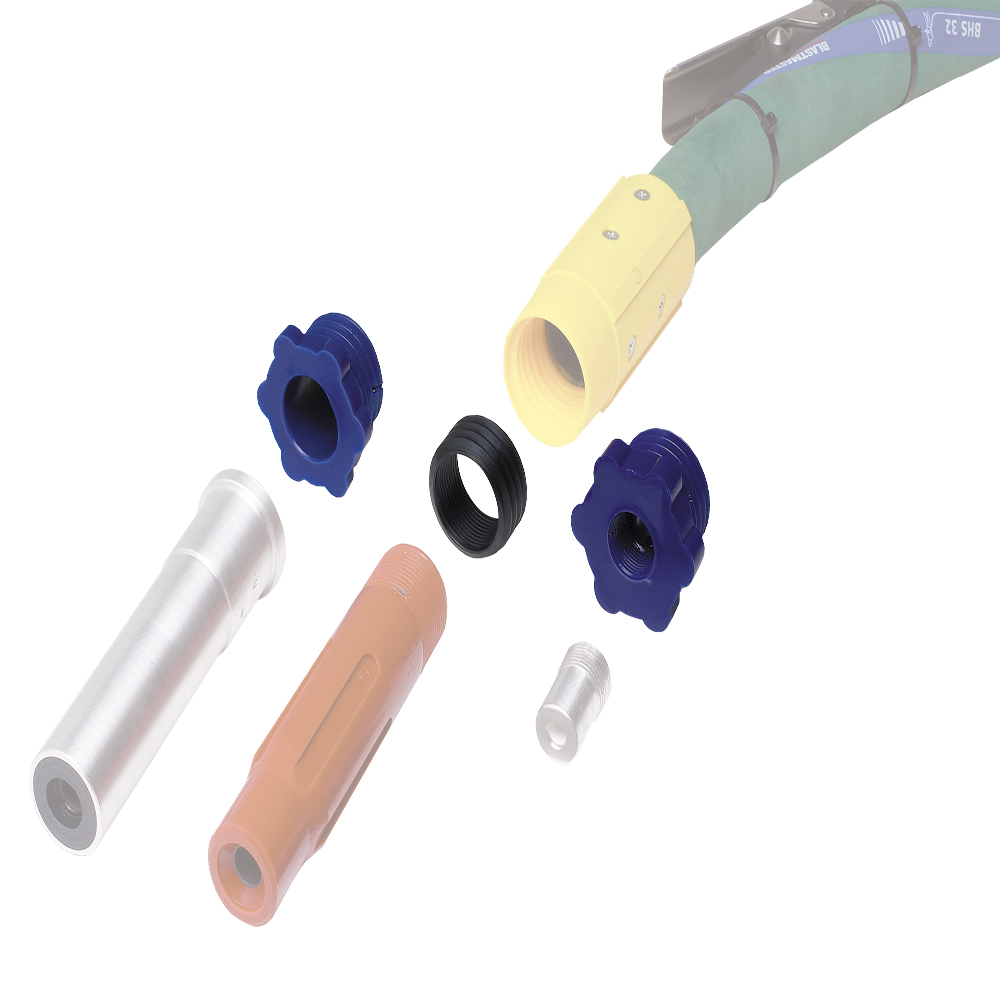

Refresh your Tite Space Invader Blasting Kit with replacement repair rods. Comes in various lengths from 30 - 152 centimetres.

- Durable and long-lasting construction

- Easy-to-use design for quick repairs

- Compatible with a variety of pipe sizes and materials

-

Tite-Space nozzles are angle nozzles, designed for use in areas that are especially difficult to access, and feature:

- 3/8" NPT Thread in either Male or Female configuration

- Male version has brass threads and requires a minimum opening clearance of 1". This version is 1-7/8" long.

- Female version has steel threads and requires a minimum opening clearance of only ¾". This version is 3-1/8" long.

- These nozzles are often used in conjunction with our Tite Space Invader Blasting Kit, available here

- Angle options include:

- 45° & 60° forward blast

- 90° right angle blast

- 135° reverse blast

- Some options available in double, triple or quad orifices in addition to single.

- Note: Using nozzles with multiple orifices will multiply the compressed air CFM requirement accordingly.

- Stock version uses tungsten carbide lining.

-

The blast nozzle for the ConeBlast Internal Pipe Blaster is a key element in controlling the volume of air/abrasive flow. It is subject to high wear and is a common replacement part. Additional details:

- Sizes. Two sizes are available, depending on the capacity of your compressed air source.

- BNAFR8 requires 250CFM

- BNARF10 requires 400CFM

- (The size variants are interchangeable.)

- Construction. These nozzles are made from tungsten carbide. For large pipe-cleaning projects, contact us for options on longer-life versions.

- Sizes. Two sizes are available, depending on the capacity of your compressed air source.

-

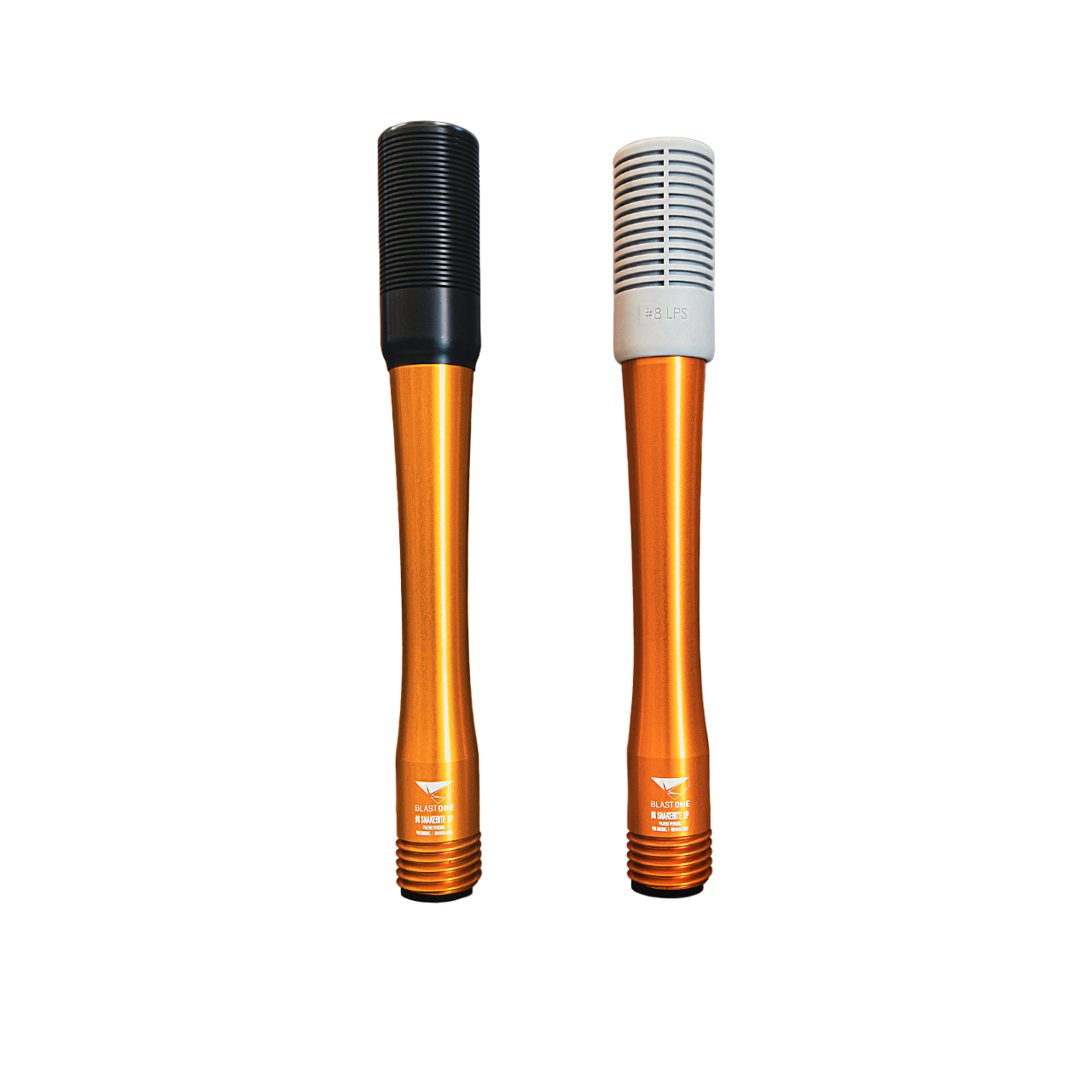

BlastOne's SnakeBite Blast Nozzle Silencers are revolutionary replacements designed exclusively for the SnakeBite family of nozzles. These silencers enhance workplace safety and operator comfort, making them ideal for blasting in noise-sensitive environments while maintaining exceptional performance.

- Replacement silencers for the SnakeBite family of blast nozzles

- Up to 45% less operator fatigue

- Up to 16dB noise reduction

- 2 versions available

- Standard Pressure Silencer effective between 90-110 psi

- Low Pressure Silencer effective between 70-90 psi

-

All the power. Half the size!

BlastOne's SnakeBite Flex Silenced Blast Nozzle is the ultimate solution for blasting in tight spaces without compromising power or performance. Exclusively engineered by BlastOne, this compact nozzle delivers all the benefits of the SnakeBite family, including noise reduction and reduced operator fatigue, while being small enough to navigate hard-to-reach areas with ease.- Up to 16dBA noise reduction

- Up to 45% less fatigue compared to standard blast nozzles

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slimline ergonomic nozzle jacket

- Standard contractor nozzle inlet thread

- Designed to optimise the use of GMA garnet

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

Act quick! Limited supply.

-

BNSBXQ10-1BlastOne's SnakeBite Strike #10 Silenced Blast Nozzle is engineered to deliver the highest productivity in hand-held blasting, making it an essential tool for professionals tackling extensive surface preparation tasks. This innovative nozzle, exclusively developed by BlastOne, offers unparalleled performance with significantly reduced operator fatigue.

- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

BNSBXQ10-1BlastOne's SnakeBite Strike #10 Silenced Blast Nozzle is engineered to deliver the highest productivity in hand-held blasting, making it an essential tool for professionals tackling extensive surface preparation tasks. This innovative nozzle, exclusively developed by BlastOne, offers unparalleled performance with significantly reduced operator fatigue.- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

-

The world's quietest blast nozzle!

BlastOne's SnakeBite XQ Silenced Blast Nozzle is engineered to be the world's quietest blast nozzle, prioritizing both operator safety and comfort. This innovative nozzle, exclusively designed by BlastOne, significantly reduces noise levels while enhancing performance, making it an essential tool for professionals in the blasting industry.- Up to 16dBA noise reduction

- Up to 45% less fatigue compared to standard blast nozzles

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slimline ergonomic nozzle jacket

- Standard contractor nozzle inlet thread

- Designed to optimise the use of GMA garnet

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

Act quick! Limited supply.

-

The Ultra-Tuff Extended Life Silicon Nitride Blast Nozzle (SKU: P-BNULTRA) is built for industrial blasting, lasting twice as long as standard nozzles while being lightweight and highly efficient. Its Venturi design boosts productivity by up to 40%, and the durable silicon nitride liner with a shock-absorbent polyurethane jacket ensures exceptional performance. Click for Buying Guide Features:

- Venturi bore: 40% faster production than straight bore nozzles.

- Thread options: Contractor (2” / 50mm) and Fine (1-¼” / 32mm).

- Orifice sizes: #3–#8 to suit various tasks.

- Throat Entry:

- 1″ throat entry on #3 and #4 Contractor thread AND all Fine thread options

- 1-¼” throat entry on #5, 6, 7, and 8 Contractor threads

- Silicon nitride liner: Longer life, lighter than tungsten carbide.

- Polyurethane jacket: Protects against shocks and jams in metal holders.

- Lightweight: Reduces operator fatigue, half the weight of tungsten carbide.

-

BNCBC6M

- Curved "Banana" Blast Nozzle

- Made from Boron Carbide which is the longest lasting material used for blast nozzles

- Size listed is a #6, which is 3/8" internal diameter

- Sizes #4 and #5 are available, but not very common - call to order

- Has a Medium 3/4" Thread - Requires a special nozzle holder adapter

- Use a HFNHA20 Medium Thread to Contractor Thread Adapter

- Sold Individually

BNCBC6M- Curved "Banana" Blast Nozzle

- Made from Boron Carbide which is the longest lasting material used for blast nozzles

- Size listed is a #6, which is 3/8" internal diameter

- Sizes #4 and #5 are available, but not very common - call to order

- Has a Medium 3/4" Thread - Requires a special nozzle holder adapter

- Use a HFNHA20 Medium Thread to Contractor Thread Adapter

- Sold Individually

-

Click for Buying Guide

- 2" UNC (50mm) Contractor thread

- 1¼" (32mm) wide throat entry, extra long venturi

- Extra long venturi increases performance by up to 30%

- SiALON II grade silicon nitride liner

- Aluminum jacket and thread with urethane cushioning

- New feature: Non-slip knurl

-

Introducing the Supersonic Tungsten Carbide Blast Nozzle (SKU: P-BNATLW) with a 1 ¼" throat entry and durable aluminum jacket - a contractor's top choice for blasting efficiency.

- 2" UNC (50 mm) coarse Contractor thread

- 1 ¼" (32 mm) wide throat entry, long venturi

- Tungsten carbide liner

- 'The Original' Contractor favourite

- Standard weight aluminum jacket and thread

- Use HF G32P nozzle washers

-

BNASB15MThe "Jumbo RotorBlast Blast Nozzle 5/16" (SKU: BNASB15M) is a high-quality tungsten carbide nozzle, perfectly designed for RotorBlast internal pipe blasting with a 5/16" (8.0mm) orifice and medium thread.

- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 5/16" (8.0mm) Orifice, Medium Thread

BNASB15MThe "Jumbo RotorBlast Blast Nozzle 5/16" (SKU: BNASB15M) is a high-quality tungsten carbide nozzle, perfectly designed for RotorBlast internal pipe blasting with a 5/16" (8.0mm) orifice and medium thread.- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 5/16" (8.0mm) Orifice, Medium Thread

-

BNASB17M

- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 3/8" (9.5mm) Orifice, Medium Thread

BNASB17M- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 3/8" (9.5mm) Orifice, Medium Thread

-

- 3/4" NPSM (20mm) 'M' thread

- 1/2" (13mm) throat entry

- Straight bore

- Tungsten carbide liner

- Aluminum jacket and thread

- Use HF GFBS-P nozzle washers (1 included)

A TIP ON WHEN TO REPLACE YOUR SAND BLAST NOZZLE

Even a very small increase in blasting nozzle size will result in a very large increase in ‘air and abrasive consumption’. When worn 1/16” (2mm) larger, it is time to be replaced. Use a size analyzer kit to check your nozzle regularly (we recommend at least ONCE PER WEEK). You’ll be surprised how much your production decreases with a worn sand blasting nozzle! Wet blasting & WIN (Water Induction) also available

SANDBLASTING & ABRASIVE BLAST NOZZLES

NOTE: Efficiency drops 1.5% for every 1 psi below 100 at the sand blasting nozzle. This means a 14% efficiency drop at 90 psi, 26% efficiency lost at 80 psi and almost half lost at 60 psi. Efficiency goes up as pressure increases. 120 psi improves performance by 30%. Actual efficiency increase/ decrease will vary depending on abrasive type and size, blast nozzle type, size and wear, hose sizes and wear, temperature, moisture content of compressed air, etc. Use a abrasive wet or dry blast nozzle pressure gauge to measure air pressure at the nozzle. Make allowance for increased air consumption due to wear, air leaks, breathing airline filter, respirator breathing air and any pneumatic equipment using air from the compressor. A good rule of thumb is to use a compressor twice the capacity of the grit consumption.

My Account

My Account

Angled Blast Nozzles

Angled Blast Nozzles General Purpose Nozzles

General Purpose Nozzles Internal Pipe (ID) Nozzles

Internal Pipe (ID) Nozzles Short / Compact Nozzles

Short / Compact Nozzles Silenced / Quiet Nozzles

Silenced / Quiet Nozzles Nozzle Tools Parts & Adapters

Nozzle Tools Parts & Adapters Wet-Blast, Specialty & Other Nozzles

Wet-Blast, Specialty & Other Nozzles Nozzle Lights & Accessories

Nozzle Lights & Accessories