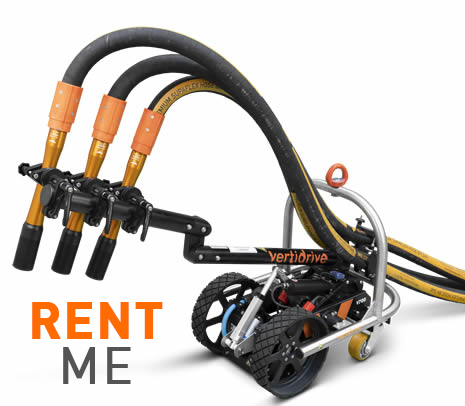

3 Reasons contractors love the Vertidrive remote-controlled blasting robot.

- 3X faster than a single blaster with production rates up to 350 sqft per hour.

- Save money by eliminating cost of scaffolding for high surfaces.

- Safety is improved by distancing the operator from the nozzle as well as eliminating the need for elevated blasting

Below are 7 insights to help the operator maximize production rates when driving the VertiDrive unit:

1. Optimize the DRIVING speed

The speed of the VertiDrive is an important factor in productivity. Too fast, and there will be bands of the surface that are under blasted. Too slow and there will be overlapping swings of the arm where you are effectively blasting the surface twice.

2. optimize the swingarm speed

Alongside the speed of the robot, the speed of the swingarm is also crucial. If the swingarm is too slow the robot is basically over blasting the surface. If the swingarm is set too fast, it may under blast and not achieve the necessary profile. Setting the optimal swingarm pace can accomplish the necessary profile in a single swing.

3. AUTOMATE WITH the step time function

The VertiDrive robot will automatically advance itself after each swing is finished.

4. Improve your visibility

Oftentimes, the VertiDrive will be quite a distance from the operator below and due to this distance and blast dust, it’s difficult to determine if the speed of the swing arm and robot are optimally blasting the surface. Two ways to counter this visual impairment is by using a low dust media like GMA Garnet as well setting the robots speeds at an eye-level view to test for optimal setup. If the robot’s pacing is found to be optimal at the lower level you can see, you can trust the same is occurring at distant heights or beneath the dust cloud.

5. Ensure proper equipment maintenance

Proper maintenance will ensure the VertiDrive experiences minimal downtime as well as performs safely during operation. If you don’t schedule your maintenance, your equipment will schedule it for you.

6. Train your operators

A properly trained operator will understand which situations, surfaces, curvatures, etc are problematic, unsafe, or outside the capabilities of the robot. Trained personnel help to promote productivity and safety on job sites.

7. Connect to your blast pot

Consider connecting the VertiDrive robot to the blast pot. Doing so allows remote activation and termination of the blast pot so you don’t have to scream at your colleague. It also improves safety by allowing operators to remotely shut off the pressure if something goes wrong.

My Account

My Account