Blasting, UHP & Site Equipment

Showing 226–240 of 322 results

-

SBMGS

Heavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops.

The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.

SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops.

The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.

-

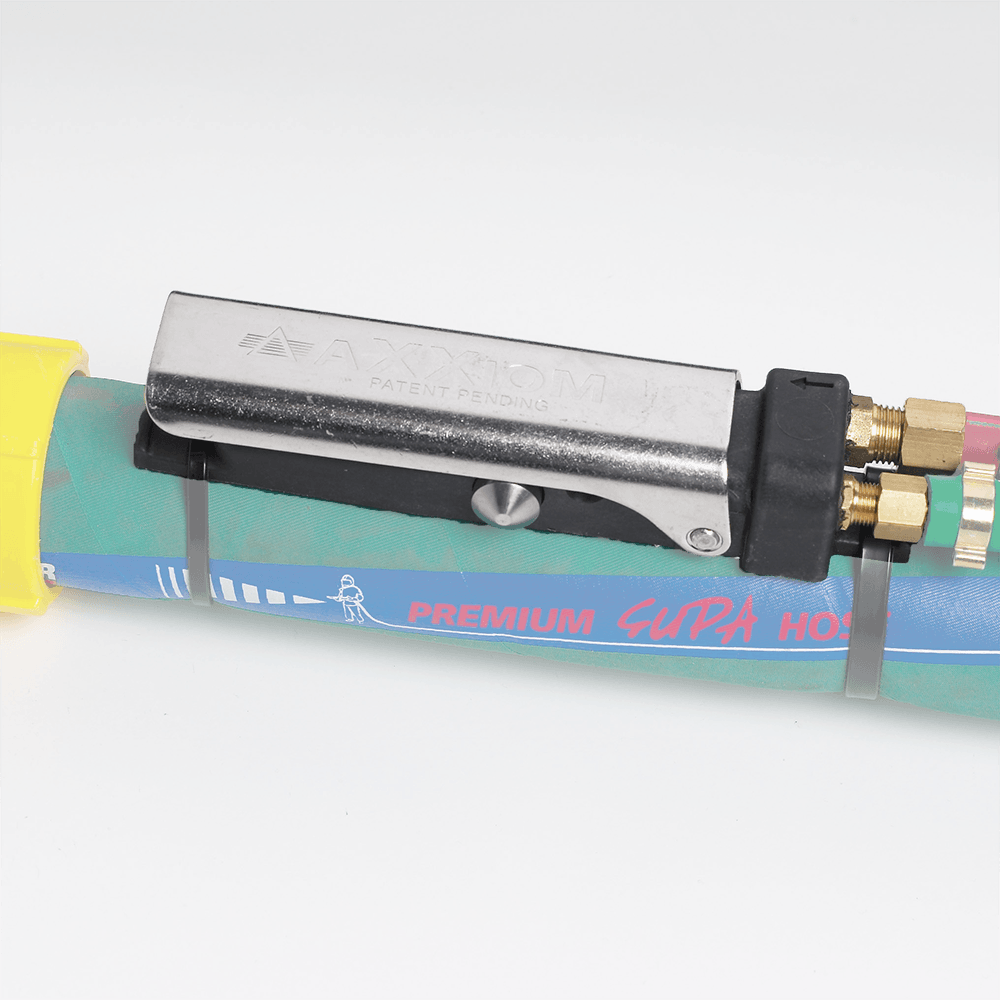

The Threaded Blast Quick Couplings (SKU: P-HFTC) ensure secure and efficient connections between metering valve outlets and blast hoses, available in both Standard and MegaMax configurations. Ideal for high-production blasting, these couplings support various material options and feature full-flow capabilities for enhanced performance. Key Features:

- 2-claw threaded coupling designed for metering valve outlets.

- Unthreaded QC couplings are used on blast hoses.

- Available in Aluminum, Brass, Steel, and Nylon.

- Supplied with factory-fitted gaskets:

- HFGMRLP for Aluminum, Brass, and Steel

- HFGPCG for Nylon with integral springlock pin

- Two configurations: Standard and MegaMax.

- MegaMax couplings offer full-flow design for increased PSI, ideal for high-production tasks with 1.5" or 2" ID blast hoses.

- Requires an adapter to connect Standard and MegaMax couplings.

- Compatible with SB1, SB2, SB-1, and SB-2 industry sizes.

- Thread sealant or tape recommended for airtight connections.

- Use coupling lock pins and whipchecks to ensure safety.

-

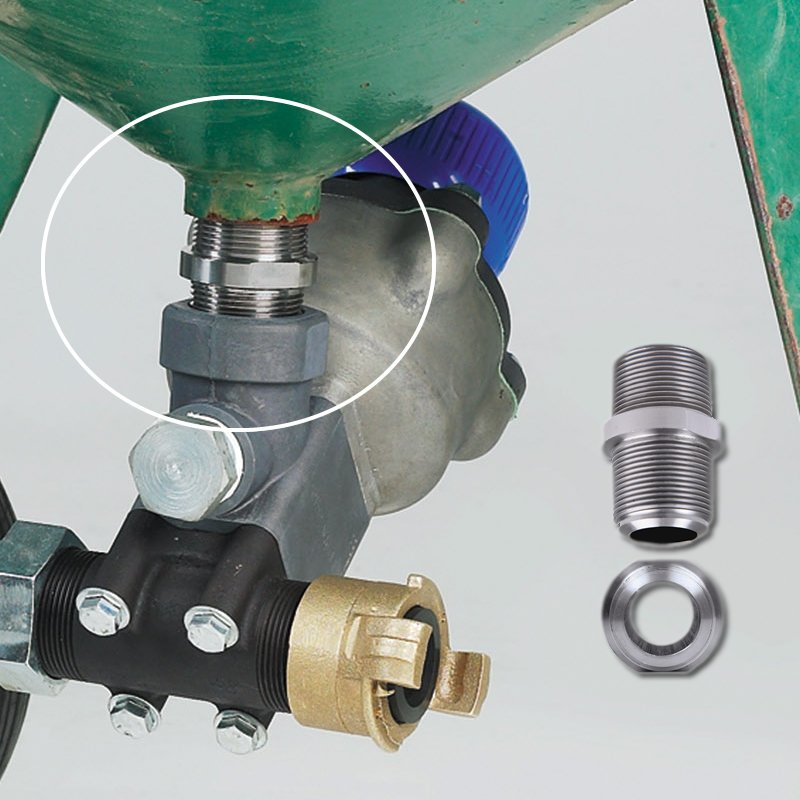

GV212800020

- 1-1/4" Heavy Duty Media Inlet Nipple

- MicroValve Series II, 1-1/4 x 1-1/2'' (32 x 38mm)

GV212800020- 1-1/4" Heavy Duty Media Inlet Nipple

- MicroValve Series II, 1-1/4 x 1-1/2'' (32 x 38mm)

-

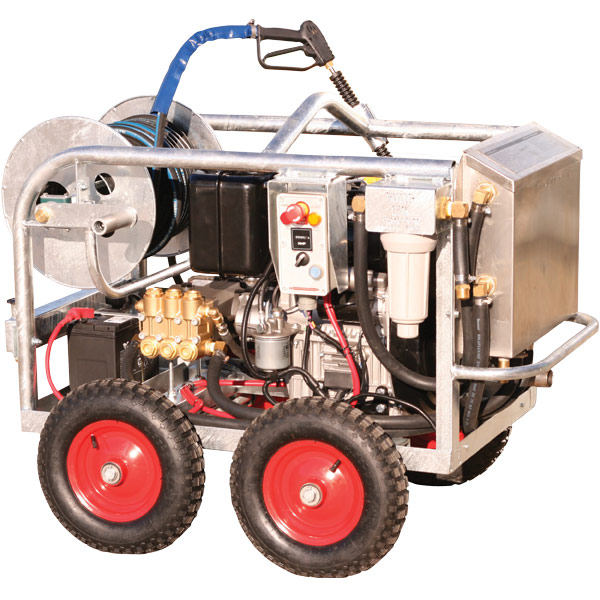

RMUBD24M50CBlastOne UBD24M-50C HP Water Blast unit rated for operation at up to 350 bar/5,000 psi, 21 LPM. Includes the following features:

- Kohler 24HP Diesel Engine

- Hawk HP Triplex Pump

- Heavy duty Hose Reel

- Stainless Water Header Tank with low level shut down

- Heavy duty industrial water filter assembly

- Large Fuel Tank

- HP 400 Bar Cleaning Gun and Lance with fan nozzle

- 20M HP Hose Assembly

RMUBD24M50CBlastOne UBD24M-50C HP Water Blast unit rated for operation at up to 350 bar/5,000 psi, 21 LPM. Includes the following features:- Kohler 24HP Diesel Engine

- Hawk HP Triplex Pump

- Heavy duty Hose Reel

- Stainless Water Header Tank with low level shut down

- Heavy duty industrial water filter assembly

- Large Fuel Tank

- HP 400 Bar Cleaning Gun and Lance with fan nozzle

- 20M HP Hose Assembly

-

BA840800079

- Essential Safety Item for Megablaster Pot closures

- Designed and installed on all Schmidt Bulk Pots since release in 2010

- Able to be retrofitted to Schmidt Bulk Pots in any of BlastOne Locations

- Ensures that correct operating procedures are followed when opening the fill port.

- Fits over camlock bolts and ensures all bolts remain in the lugs until all cams are fully disengaged, ensuring that the lid can not blow open

BA840800079- Essential Safety Item for Megablaster Pot closures

- Designed and installed on all Schmidt Bulk Pots since release in 2010

- Able to be retrofitted to Schmidt Bulk Pots in any of BlastOne Locations

- Ensures that correct operating procedures are followed when opening the fill port.

- Fits over camlock bolts and ensures all bolts remain in the lugs until all cams are fully disengaged, ensuring that the lid can not blow open

-

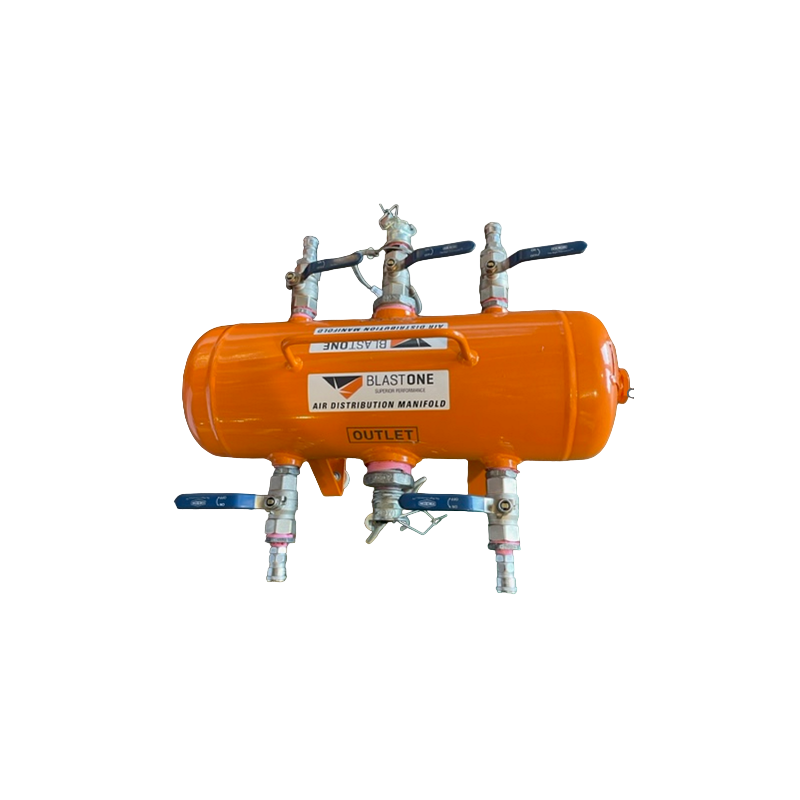

- Installed at blast machine inlet for final stage moisture droplet removal before air enters blast machine

- Tangential flow and elementless design

- Minimal pressure loss for peak blasting productivity

- Supplied with manual drain valve

- Optional autodrain accessory available

- Male threaded inlet and outlet ports

- Inlet fitting or ball valve not supplied - order separately

- Specify Size - 250cfm or 400cfm, based on the size of your blast nozzle and compressor

- Includes internal stainless steel coalescer

-

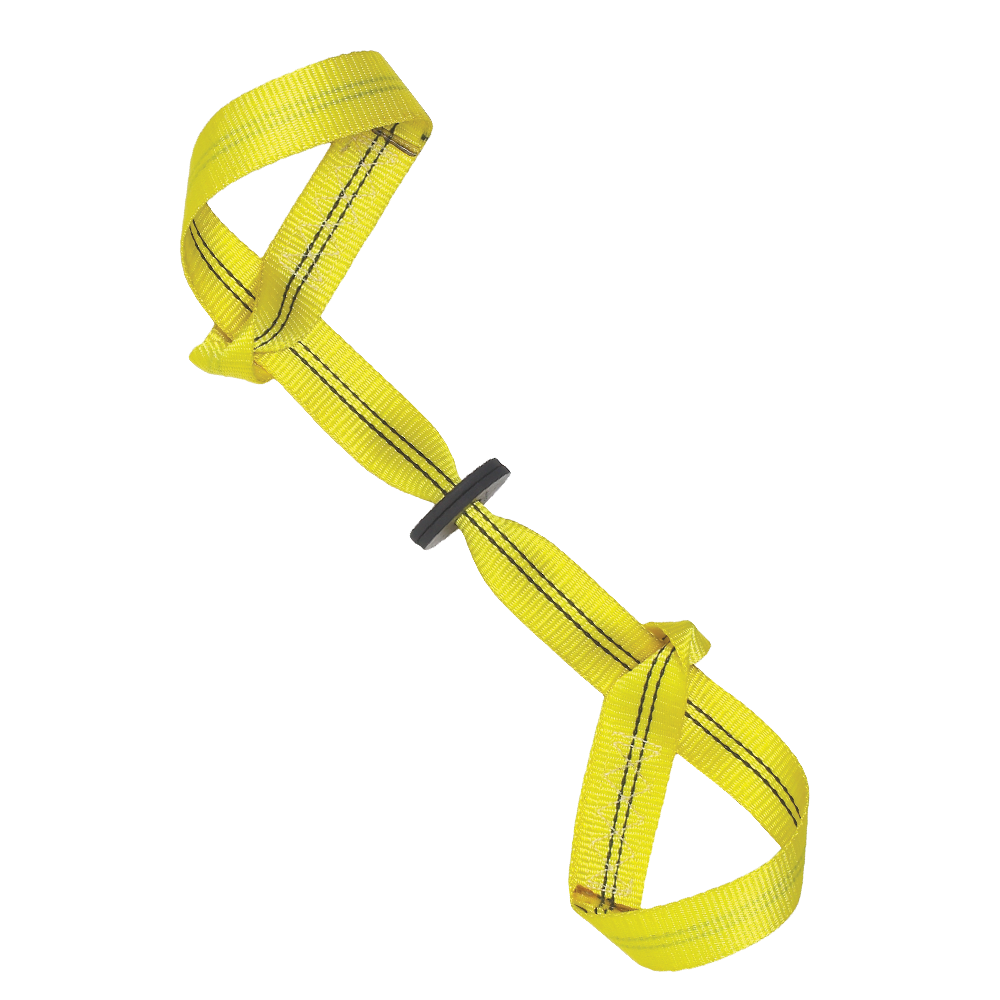

- Nylon webbing whipchecks - easier to install, less damaging to hose and will provide a longer service life

- The use of a whpcheck restraint is mandatory on all hoses. If you have any questions about the best restraint to use, please contact us directly.

-

BAP5The Large Seating Ring – Clemco Style offers a reliable replacement solution for maintaining your Clemco blast machine’s optimal sealing performance. Designed specifically for large-scale compatibility, it helps ensure proper functionality of the pop-up valve system, reducing downtime and keeping your operation running smoothly. Key Features & Specifications:

- High-quality replacement seating ring designed for Clemco blast machines

- Large size ensures proper sealing and efficient system performance

- Supports pop-up valves (sold separately) for seamless integration

- Ideal for restoring and maintaining blast machine functionality

BAP5The Large Seating Ring – Clemco Style offers a reliable replacement solution for maintaining your Clemco blast machine’s optimal sealing performance. Designed specifically for large-scale compatibility, it helps ensure proper functionality of the pop-up valve system, reducing downtime and keeping your operation running smoothly. Key Features & Specifications:- High-quality replacement seating ring designed for Clemco blast machines

- Large size ensures proper sealing and efficient system performance

- Supports pop-up valves (sold separately) for seamless integration

- Ideal for restoring and maintaining blast machine functionality

-

Abrasive blasting hopper lid and mesh screen

-

- Lid and Screen Set designed to suit blast pots

- Hole size 1/4” (6 mm)

- Screen sieves foreign matter out of the abrasive

- Lid keeps moisture, rain, dew, etc – out of the blast machine

- Select the size to suit diameter of your blast pot 12" 18" 24"

- Fit most portable blast machines, made by Schmidt abrasive blasting, Axxiom Manufacturing, clemco

-

-

GV212500012

- Size: 1 ¼" (31.75 mm)

- Heavy duty long life pot connector to prevent the top thread of the MicroValve from wearing

- Pot Connector - Long Life

GV212500012- Size: 1 ¼" (31.75 mm)

- Heavy duty long life pot connector to prevent the top thread of the MicroValve from wearing

- Pot Connector - Long Life

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Air Compressors

Air Compressors Air Dryers

Air Dryers Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Deadman Handles

Deadman Handles Abrasive Metering Valves

Abrasive Metering Valves Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment Portable Lighting

Portable Lighting Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings