Contractor Blast Pots

Contractor-grade blast pots from BlastOne deliver rugged, high‑performance abrasive blasting solutions for a wide range of jobsite applications. From compact 3.5 cu ft units for tight spots to heavy‑duty 20 cu ft dual‑outlet systems for production blastrooms, these Schmidt® models support wet or dry blasting, dust‑sensitive environments, and trailer‑mounted operations. Each pot features TeraValve or Thompson metering, moisture control, and pneumatic deadman safety to maximize efficiency, portability, and compliance on every job.

These pots are built to handle garnet, steel grit, soda, and specialty abrasives with precise pressure regulation, reliable flow control, and easy service access. Whether you’re handling small-scale patch‑up work or large surface prep, this lineup gives you the right tool to match jobsite requirements and boost blasting productivity.

Showing all 10 results

-

- Manufactured by Schmidt Abrasive Blasting & Axxiom Manufacturing to BlastOne specifications

- Valving system designed to have a maximum of 3psi pressure drop

- Specified Capacity (approx)

- 3.5 cu ft / 99 litres

- Abrasive Capacity (approx)

- Garnet - 230 kg

- Steel Grit - 390 kg

- Pressure Rating: 150psi

- Includes: Moisture separator and inlet fitting

-

BMS65MB-PThe "Mist Blaster For Wet Abrasive Blasting" (SKU: BMS65MB-P) offers a versatile blasting experience with the capability for dustless vapor or dry, washdown, and blowdown. Featuring a pot capacity of 6.5 cu ft and a blast pressure range of 75-150 psi, it's an efficient solution for both wet and dry blasting needs.

- Versatile capability - Dustless Vapor or Dry, Washdown and Blowdown

- Pot capacity 6.5 cu ft / 184 litres

- Blast pressure ranging from 75-150 psi

- Single Outlet with Tera Valve XL metering valve

- Has secondary wheels to ease transportation

BMS65MB-PThe "Mist Blaster For Wet Abrasive Blasting" (SKU: BMS65MB-P) offers a versatile blasting experience with the capability for dustless vapor or dry, washdown, and blowdown. Featuring a pot capacity of 6.5 cu ft and a blast pressure range of 75-150 psi, it's an efficient solution for both wet and dry blasting needs.- Versatile capability - Dustless Vapor or Dry, Washdown and Blowdown

- Pot capacity 6.5 cu ft / 184 litres

- Blast pressure ranging from 75-150 psi

- Single Outlet with Tera Valve XL metering valve

- Has secondary wheels to ease transportation

-

- Manufactured by Schmidt to BlastOne specifications

- High Performance abrasive blasting equipment

- Valving system designed to have a maximum of 3psi pressure drop

- Specified Capacity (approx)

- 6.5 cu ft / 185 litres

- Abrasive Capacity (approx)

- Garnet - 430 kg

- Steel Grit - 700 kg

- Pressure Rating: 150psi

- Includes: Moisture separator and inlet fitting

-

BMS1172TERA

- Manufactured by Schmidt to BlastOne specifications

- High Performance abrasive blasting equipment

- Valving system designed to have a maximum of 3psi pressure drop

- Specified Capacity (approx)

- 11.7 cu ft

- Abrasive Capacity (approx)

- Garnet - 700 kg

- Pressure Rating: 150psi

- Includes: Moisture separator and inlet fitting

BMS1172TERA- Manufactured by Schmidt to BlastOne specifications

- High Performance abrasive blasting equipment

- Valving system designed to have a maximum of 3psi pressure drop

- Specified Capacity (approx)

- 11.7 cu ft

- Abrasive Capacity (approx)

- Garnet - 700 kg

- Pressure Rating: 150psi

- Includes: Moisture separator and inlet fitting

-

FOR RENTAL OR PURCHASE

- Combination Skid - MistBlaster and AirDryer Package

- Capable of doing wet and dry blasting - ultimate flexibility for any job!

- 6.5 cu. ft. Schmidt Blast Pot with MistBlaster Conversion

- Teravalve XL Abrasive Metering Valve

- 400cfm Moisture Removal System (Select Deliquescent Air Dryer or Squat AfterCooler)

- 189 liter water tank & pump

- Select if you do or don't want the Operator Accessories Kit (RPB Breathing air filter and GX4 CO Monitor, 5cm Bull hose, 3.175cm SupaFlex Blast Hose, Nova 3 Blast Helmet, and #6 Blast Nozzle)

-

- Wet blast or dry blast with a single unit

- Minimal water usage (less than 1 pint / ½ litre per minute) with proprietary Schmidt M.I.S.T.™ technology that allows precise control of the amount of water injected into the air stream while blasting

- Set and forget switching between machine modes

- Abrasive tank is “dry” so there is no need to drain water to refill with abrasive. This creates a significantly cleaner job site and is more efficient

- Industry-leading productivity and reliability from Schmidt abrasive blasting technology

- Schmidt Tera Valve™ XL abrasive metering valve offers precise and repeatable control of a wide range of coarse or fine abrasives

- Wide range of blasting pressure capabilities from 10 to 150 psi

- Toggle between wet blast, dry blast, and blow-off using a single control panel

- Increased portability

-

BMPIPSYSL375ACT

- Dual Wheeled Trailer Mounted abrasive blasting equipment

- BMS6.5 blast machine with Thompson Valve outlet

- 400 cfm AirPrep Air Drier

- 375 cfm 150 psi diesel air compressor

- Breathing air filter

- Carbon monoxide alarm

- Tool box

- Hose rack

- Room for 1 skid of abrasive

- Dustless Vapor Blasting

BMPIPSYSL375ACT- Dual Wheeled Trailer Mounted abrasive blasting equipment

- BMS6.5 blast machine with Thompson Valve outlet

- 400 cfm AirPrep Air Drier

- 375 cfm 150 psi diesel air compressor

- Breathing air filter

- Carbon monoxide alarm

- Tool box

- Hose rack

- Room for 1 skid of abrasive

- Dustless Vapor Blasting

-

The Schmidt® M-Series Multi-Media Blasters are built for pros who need one blast pot that handles it all. From light cleaning with soda to aggressive steel grit work, this series delivers full control, rugged performance, and reliable media flow—job after job.

- Blasts a wide range of abrasives: soda, grit, plastic, glass, and more

- Available with choice of the tried-and-true Thompson II or the latest TeraValve XL, for the ultimate in precision abrasive metering. Both come with a slotted tungsten carbide sleeve.

- G3 Trigger Deadman now standard across all models with the compact BAABS also included in all except the Mini M-Series.

- Pressure and tank regulators dial in your blast profile for each job. Blasting pressure can be set from 10 to 150 PSI.

- Media vibrator boosts flow performance for lighter abrasives

- Quick-detach valve and media shutoff for simplified service

- Available sizes: Mini M-Series (0.9 cu ft), M-11 (1.5 cu ft), M-21 (2.0 cu ft), M-31 (3.0 cu ft)

-

BMS200

- 20.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Dual outlet Thompson Valve II abrasive metering valves

- Approx 1350 kg garnet abrasive capacity

- Comes with two pneumatic deadman handles and two lengths of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

BMS200- 20.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Dual outlet Thompson Valve II abrasive metering valves

- Approx 1350 kg garnet abrasive capacity

- Comes with two pneumatic deadman handles and two lengths of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

-

BMS1001TV

- 10.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Single outlet Thompson Valve II abrasive metering valve

- Approx 670 kg garnet abrasive capacity

- Comes with pnuematic deadman handle and 20m of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

BMS1001TV- 10.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Single outlet Thompson Valve II abrasive metering valve

- Approx 670 kg garnet abrasive capacity

- Comes with pnuematic deadman handle and 20m of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

When selecting your contractor blast pot, consider:

- Pot capacity & output: Pick the right size for workspace and abrasive requirements—from compact units for spot work to high-volume models for full panels or trailers.

- Valving & flow control: TeraValve XL provides ultra‑precise metering, while Thompson valves offer rugged simplicity—choose based on material flow needed.

- Wet vs dry blasting: Wet capable pots like the AmphiBlast and MistBlaster reduce dust and allow versatile media use, ideal for environmentally controlled sites.

- Portability & set‑up: Wheels, forklift pockets, or full trailer packages enable fast mobilization on‑site or between job locations.

We advise contacting our support team or using live chat if you’re unsure which pot matches your project or abrasive type, no setup is completed until you’ve got the right tool.

My Account

My Account

Suction Guns

Suction Guns Small Blast Pots

Small Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

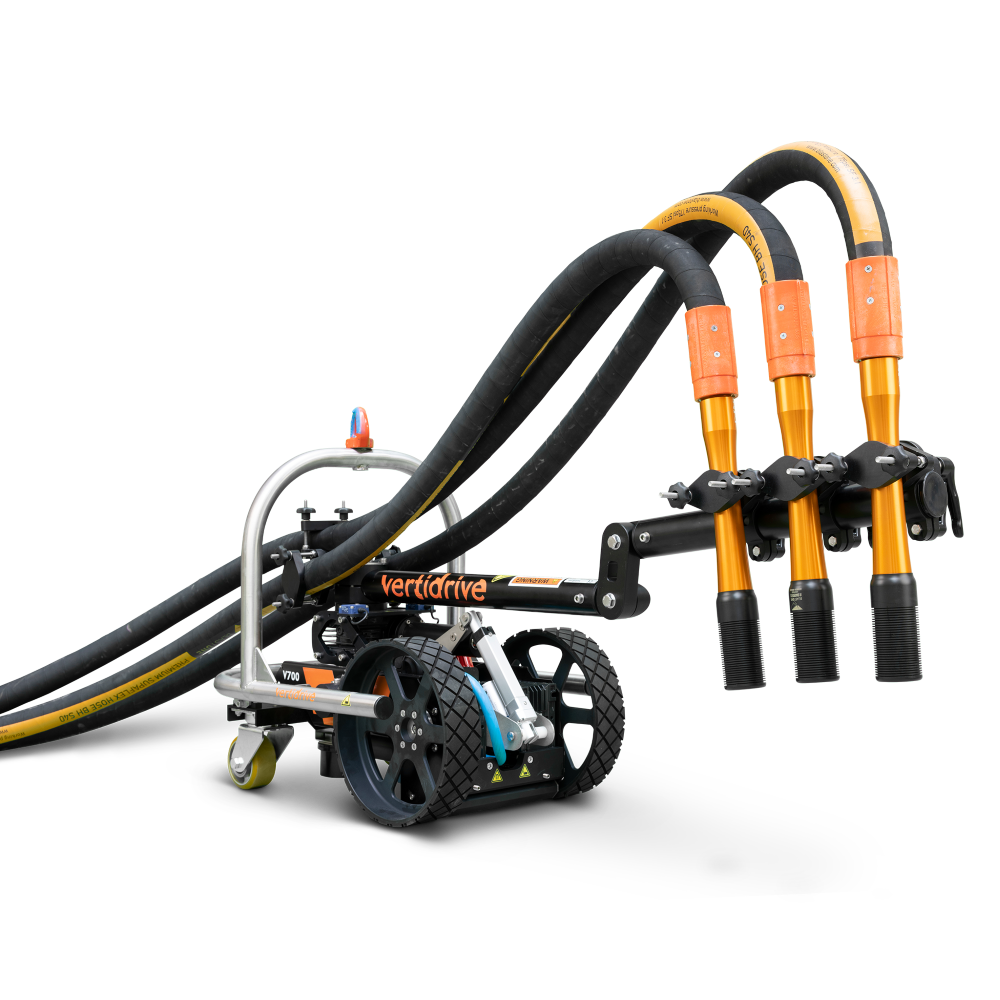

MistBlaster Wet / Dry Pots Robotic / Vertidrive Equipment

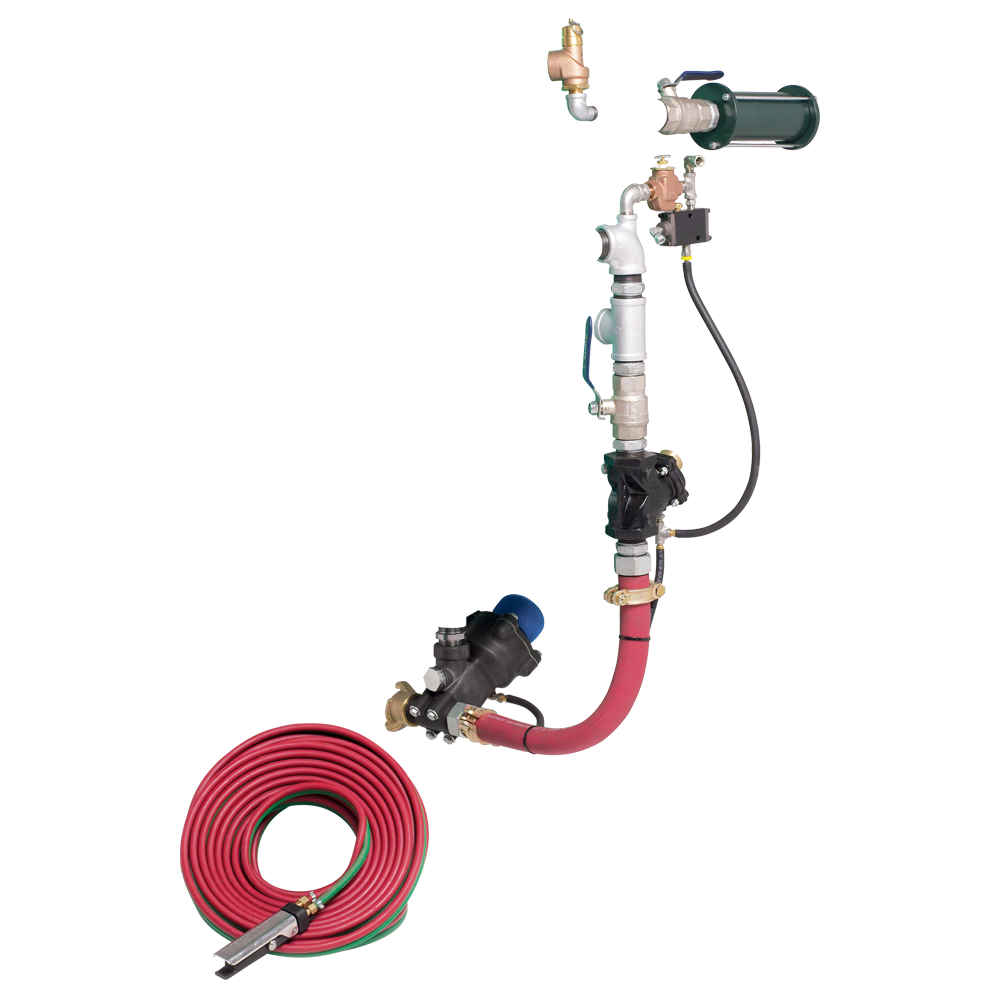

Robotic / Vertidrive Equipment Internal Pipe (ID) Systems

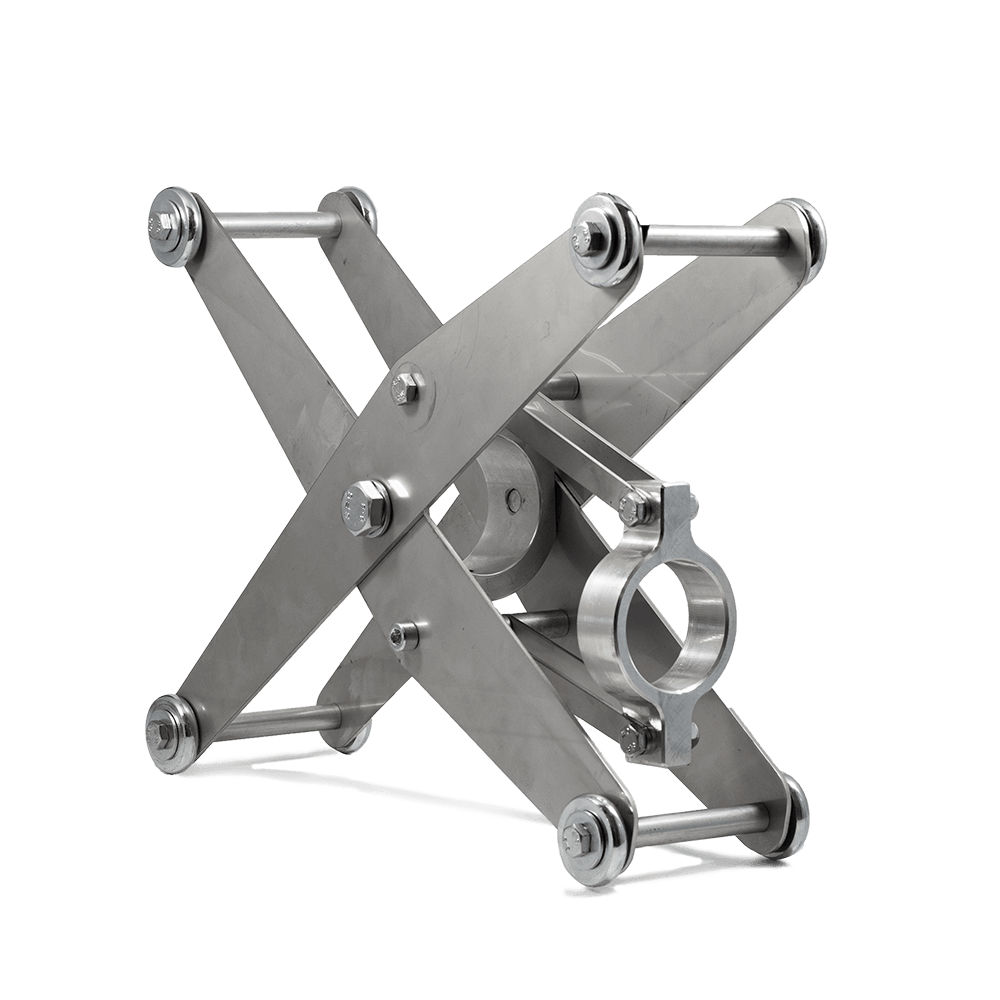

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories Blast Rooms

Blast Rooms