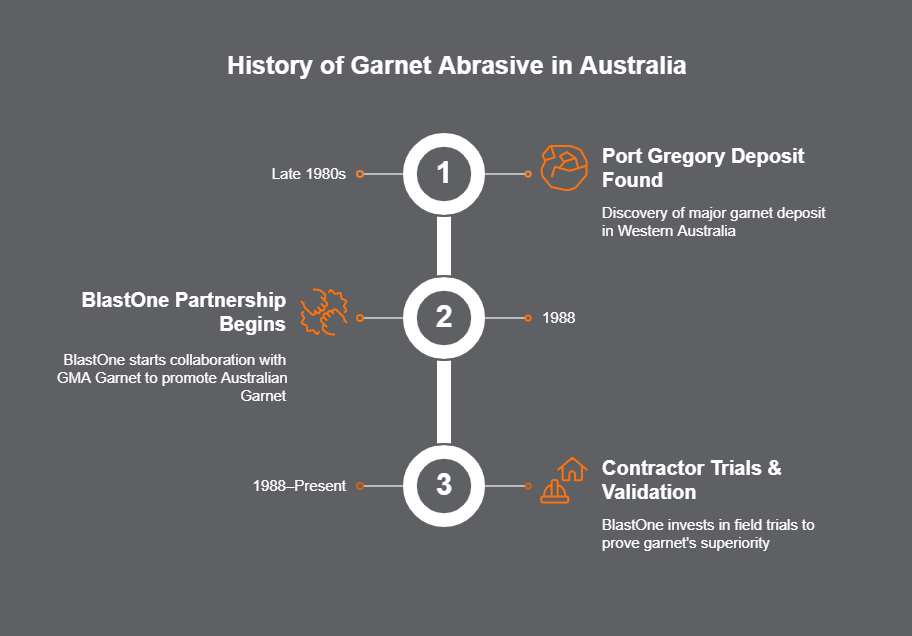

Since the discovery of a significant garnet deposit at Port Gregory, Western Australia in the late 1980s, BlastOne has proudly worked alongside Garnet Millers Australia (GMA Garnet) to champion the use of Australian Garnet as a safe, productive, and economical alternative to traditional sand and slag abrasives.

From Resistance to Revolution

Sounds simple, doesn’t it? But back in the early days, we had trouble even giving the stuff away.

Since 1988, BlastOne has invested millions into supporting thousands of contractors in testing and validating the performance of Australian Garnet — often at our own cost. Over decades of trials and field experience, GMA Garnet has proven itself as a superior abrasive media that delivers cleaner surfaces, lower consumption, and reduced dust.

What Makes Australian Garnet So Special?

Even seasoned professionals are often surprised at what sets Australian Garnet apart. Unlike other garnet sources such as those in India, GMA Garnet has undergone a unique double erosion process. This means the grains have been naturally conditioned twice — first by ancient streams and beaches, then by intense coastal winds — resulting in:

- Harder, more durable garnet particles

- Lower dust generation during blasting

- Greater efficiency and recyclability

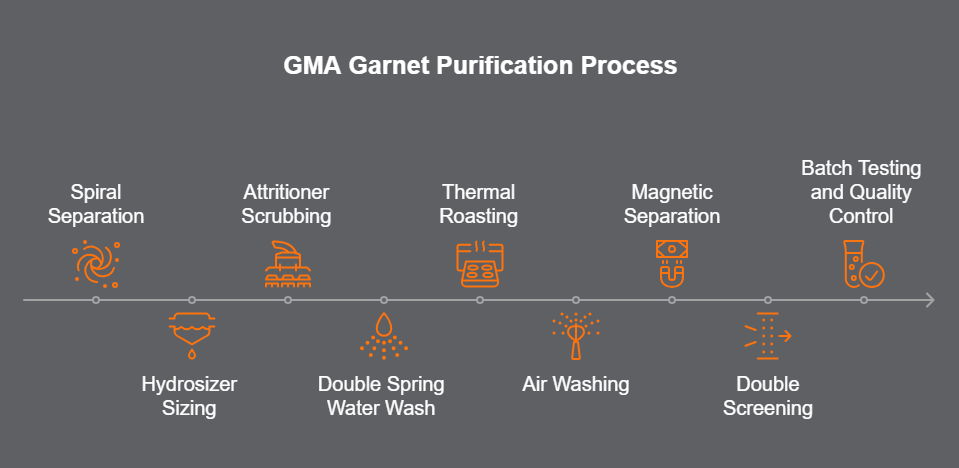

Purity Starts with the Process

GMA Garnet isn’t just scooped and bagged. Every grain undergoes a rigorous nine-stage purification process before packaging:

- Spiral Separation

- Hydrosizer Sizing

- Attritioner Scrubbing

- Double Spring Water Wash

- Thermal Roasting

- Air Washing

- Magnetic Separation

- Double Screening

- Batch Testing and Quality Control

This dedication to quality ensures consistent performance in every bag of garnet shipped worldwide.

Ultra-Low Salt = Ultra-Clean Surfaces

Australian Garnet has the lowest soluble salt levels of any garnet globally — averaging just 5–10 ppm. By contrast, the ISO standard requires less than 25 ppm.

Why does this matter? Low salt levels are essential to preventing coating failures caused by surface contamination. That’s why industry leaders trust Australian Garnet on critical infrastructure projects around the world.

Full Traceability and Quality Accountability

Every bulk bag of GMA Garnet comes labeled with a batch reference number. That number is tied to lab-tested material samples, allowing for full traceability of the following within 24 hours:

- Chloride levels

- Sieve (mesh size) analysis

- Overall quality assurance results

This level of transparency provides contractors with confidence and complete quality accountability.

“I would like to recommend the use of Australian Garnet for future projects that entail sandblasting.”

— David Maag, PCS Nitrogen, Lima, Ohio, USA

Explore More on GMA Garnet

Want to learn how to choose the right garnet grade or see performance data from real jobs?

- View the GMA Garnet Buying Guide

- Read Our Cost-Saving Case Study

- See Why Professionals Trust GMA Garnet

BlastOne has led the way in garnet blasting since 1988. If you’re planning a project or evaluating abrasive performance, get in touch with one of our experts.

My Account

My Account