Sources of Error

There are four major sources of error in determining the profile of a blast cleaned surface, which can be minimized with the following suggestions.

- Inherent Profile Variation in the surface – perform at least 3 tests per 100 square feet (10 square meters) of area.

- Contaminant particles in the anvils or tape – select a clean surface; clean and check the anvils; examine the test tape; double check any questionable readings. To indicate the size significance of seemingly tiny contaminants, please note that human hair is approx. 2 mils (50 microns) thick.

- Improper Gage – a good gauge has an accuracy of ±0.2 mils (±5 microns), closing force of 1.5N and at least one anvil 0.25” (6.3mm) diameter.

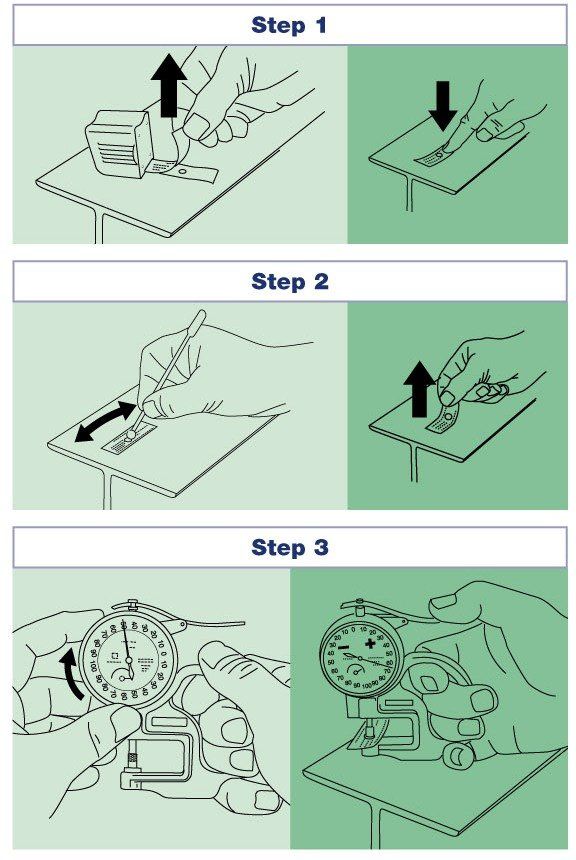

- Deficient Impressing Technique – use a profile training tool to verify the burnishing technique is correct.

DISCLAIMER: Whilst replica tape is recognized by AS1627.4, AS3894.5, ISO8503.5 and other standards, the above information and procedure does not nor shall not be taken as representing (nor intending) to be the approved nor the complying nor the standard method nor procedure for the use of replica tape. It is the responsibility of the reader and/or users of this information to separately determine and verify the correct method and procedure of use as directed or indicated in any work specifications or standards. Blast-One™ expressly disclaims any liability for the use or misuse of the above information and procedure.

My Account

My Account